Everything You Need

Download our technical specs

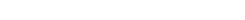

Precasteel Drawing Package

Lehigh Test Report for StayPanel™ Forms

U.S. Patent

StayPanel™ Form Brochure

MASH Compliance

FAQ

-

Overhangs are typically measured from the center of the fascia girder to the outboard face of the proposed barrier, while the soffit is measured from the outboard edge of the top flange of the fascia girder to the outboard face of the StayPanel™ form. For example, assume we have a 3'-0" overhang on a structure with a top flange width of 12"; the soffit width would be calculated by subtracting half the top flange (6") from the overhang and adding the thickness (3") of the StayPanel™ form [i.e., 3'-6" + 3" = 3"-9" soffit width].

-

The maximum overhang depends upon the width of the top flange; however, the maximum soffit width tested to date equates to 39" or 3'-3".

-

Preferably, the pipe rail should run along the centerline of the fascia girder to avoid deflections that could reflect into the deck pour, causing a washboard effect along the barrier line that may cause ponding and require remedial action. This is a relatively common effect encountered when using conventional means.

-

In stage construction, the workers can usually traverse the concrete paving machine from the side of the work zone with room for a walkway. In case of a ramp structure, where the paving machine reaches from barrier to barrier, a pick bracket located on the inside face of the StayPanel™ form can be utilized on each panel to support an aluminum pick to walk on.

-

Pipe rails can be pulled from work bridges or pulled after the deck is cured sufficiently to walk upon. Pipe supports are recovered once the deck is walkable by screwing them out of the concrete and pouring back with barrier concrete (if inside the proposed barrier pour) or a non-shrink grout, such as SikaGrout® 212.